ZASI is led by an experienced team with deep expertise in American cabinetry and global supply chain operations.

Vietnam Manufacturing

ZASI CABINET

FACTORY

Operating a 600,000 sq. ft. powerhouse in Vietnam. Delivering 120 containers of premium American-style cabinetry monthly. Scalable capacity, engineered for global partnerships.

Vietnam Manufacturing

ZASI CABINET

FACTORY

Operating a 600,000 sq. ft. powerhouse in Vietnam. Delivering 120 containers of premium American-style cabinetry monthly. Scalable capacity, engineered for global partnerships.

Management Team

ZASI is led by an experienced management team with deep expertise in American cabinetry manufacturing, quality control, and international supply chain operations.

Jason Li

Executive Vice President (EVP)

ZASI CABINETRY

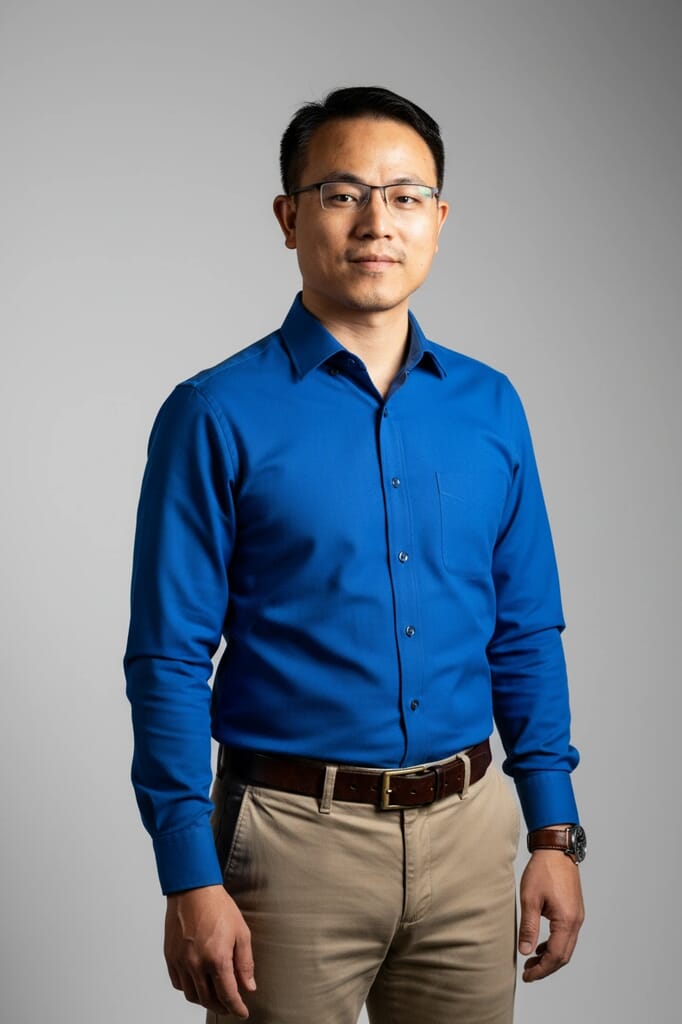

Joe Zhou

Vice President of Product Development

ZASI CABINETRY

David Li

Vice President of Sales

ZASI CABINETRY

Xiaoming Yu

Purchasing Manager

ZASI CABINETRY

James Zhang

Quality Assurance Manager

ZASI CABINETRY

Jinlong Yang

Woodworking Supervisor

(Carcase & Drawer Box Dept.)

ZASI CABINETRY

Zhenhua Zhao

Woodworking Supervisor

(Door & Face Frame Dept.)

(Door & Face Frame Dept.)

ZASI CABINETRY

Fei Yu

Finishing Department Supervisor

ZASI CABINETRY

Songtao Li

Finishing Department Supervisor

ZASI CABINETRY

Dinh Thi Ven

Packaging Supervisor

ZASI CABINETRY

Caron Wu

Human Resources Supervisor

ZASI CABINETRY

Yongkang Zhang

Equipment Engineering Supervisor

ZASI CABINETRY

Cabinet Pro

Leading the Future of Kitchen Manufacturing

ZASI is a $50M cabinet manufacturer with a 600,000 sq ft Vietnam facility, advanced European and Taiwanese equipment, and the capacity to supply 120 containers per month for both stock and custom programs in the North American market.

Where scale is never a constraint.

ZASI operates a modern manufacturing facility in Vietnam with a total area of 600,000 square feet and a workforce of over 600 skilled employees. The factory maintains a monthly production capacity of 120 x 40’ HQ containers, supporting large-scale supply for both stock programs and custom cabinetry. With an annual revenue of approximately USD 50 million, ZASI has established itself as a stable and reliable manufacturing partner in the North American cabinet market.

Facility Size: 600,000 Sq. Ft.

Monthly Capacity: 120 x 40'HQ Containers

Workforce: 600+ Skilled Employees

Annual Revenue: $50 Million

Next-Level Inventory Power

ZASI Factory boasts a massive 100,000 sq. ft. warehouse with 30-foot ceilings—purpose-built for the Koville brand and its dealers. With inventory of all 14 Koville RTA cabinet door styles, we’re ready to handle any urgent project, anytime. This strategic investment allows Koville dealers in the U.S. to cut storage costs by 50%, enjoy faster shipping, improve cash flow, and maximize profits. ZASI’s super-sized warehouse isn’t just storage—it’s your competitive advantage.

Precision Starts with the Right Tools.

ZASI Factory is equipped with a full lineup of advanced manufacturing systems to ensure precision, consistency, and scalable production. Our facility features Italian-imported automated finishing systems from Cefla, advanced door primer edge banding machines, high-precision shapers from Taiwan (SHEN KO), and industrial-grade thickness sanding machines from Sanderson. These systems allow us to achieve refined finishes, tight tolerances, and repeatable quality across different cabinet lines.

Software-powered cabinet mastery.

ZASI Cabinetry goes beyond OEM manufacturing, providing advanced ODM product design supported by a professional team proficient in 2020 Design for cabinet planning, 3ds Max and V-Ray for industrial and product rendering, and Adobe Photoshop and Lightroom for creating high-quality marketing and visual assets, ensuring clients receive fully integrated design and promotional support.

All In, All Precision.

Backed by a USD 20 million investment from Best Cheer Group, the ZASI Factory in Ho Chi Minh City integrates state-of-the-art Italian and U.S. production equipment, advanced design and engineering software, and a team of highly skilled cabinet specialists. This combination ensures precision, consistent quality, and fully supported OEM/ODM project execution.

CAPACITY

WHERE SCALE IS NEVER A CONSTRAINT.

ZASI operates a modern manufacturing facility in Vietnam with a total area of 600,000 square feet and a workforce of over 600 skilled employees.

The factory maintains a monthly production capacity of 120 x 40’ HQ containers, supporting large-scale supply for both stock programs and custom cabinetry.

With an annual revenue of approximately USD 50 million, ZASI has established itself as a stable and reliable manufacturing partner in the North American cabinet market.

The factory maintains a monthly production capacity of 120 x 40’ HQ containers, supporting large-scale supply for both stock programs and custom cabinetry.

With an annual revenue of approximately USD 50 million, ZASI has established itself as a stable and reliable manufacturing partner in the North American cabinet market.

READY STOCK

NEXT-LEVEL INVENTORY POWER.

ZASI Factory boasts a massive 100,000 sq. ft. warehouse with 30-foot ceilings—purpose-built for the Koville brand and its dealers.

With inventory of all 17 Koville RTA cabinet door styles, we’re ready to handle any urgent project, anytime.

This strategic investment allows Koville dealers in the U.S. to cut storage costs by 50%, enjoy faster shipping, improve cash flow, and maximize profits. ZASI’s super-sized warehouse isn’t just storage—it’s your competitive advantage.

With inventory of all 17 Koville RTA cabinet door styles, we’re ready to handle any urgent project, anytime.

This strategic investment allows Koville dealers in the U.S. to cut storage costs by 50%, enjoy faster shipping, improve cash flow, and maximize profits. ZASI’s super-sized warehouse isn’t just storage—it’s your competitive advantage.

EQUIPMENT

PRECISION STARTS WITH THE RIGHT TOOLS.

ZASI Factory is equipped with a full lineup of advanced manufacturing systems to ensure precision, consistency, and scalable production.

Our facility features Italian-imported automated finishing systems from Cefla, advanced door primer edge banding machines, high-precision shapers from Taiwan (SHEN KO), and industrial-grade thickness sanding machines from Sanderson.

These systems allow us to achieve refined finishes, tight tolerances, and repeatable quality across different cabinet lines.

Our facility features Italian-imported automated finishing systems from Cefla, advanced door primer edge banding machines, high-precision shapers from Taiwan (SHEN KO), and industrial-grade thickness sanding machines from Sanderson.

These systems allow us to achieve refined finishes, tight tolerances, and repeatable quality across different cabinet lines.

SOFTWARE

SOFTWARE-POWERED CABINET MASTERY.

ZASI Cabinetry goes beyond OEM manufacturing, providing advanced ODM product design supported by a professional team.

We are proficient in 2020 Design for cabinet planning, 3ds Max and V-Ray for industrial and product rendering, and Adobe Photoshop & Lightroom for creating high-quality marketing and visual assets.

This ensures clients receive fully integrated design and promotional support.

We are proficient in 2020 Design for cabinet planning, 3ds Max and V-Ray for industrial and product rendering, and Adobe Photoshop & Lightroom for creating high-quality marketing and visual assets.

This ensures clients receive fully integrated design and promotional support.

INVESTMENT

ALL IN, ALL PRECISION.

Backed by a USD 20 million investment from Best Cheer Group, the ZASI Factory in Ho Chi Minh City integrates state-of-the-art Italian and U.S. production equipment, advanced design and engineering software, and a team of highly skilled cabinet specialists.

This combination ensures precision, consistent quality, and fully supported OEM/ODM project execution.

This combination ensures precision, consistent quality, and fully supported OEM/ODM project execution.

A7 Quality Standard

A7 Quality Standard is ZASI’s production benchmark, uniting precision engineering, consistent craftsmanship, and accountable quality control.

It defines how we design, manufacture, inspect, and deliver cabinets that meet long-term performance expectations in the North American market.

A1

Authentic Materials

Premium FAS/Select hardwood and certified panels ensure durability and stability.

A2

Accurate Engineering

Precision dimensions for Inset, Framed, and Frameless systems ensure smooth installation.

A3

Advanced Craftsmanship

Joinery, panel alignment, and edging combined with expert handwork and scalable production.

A4

Assured Quality Control

In-line and final inspections check dimensions, appearance, and functionality.

A5

Aesthetic Consistency

Color consistency, aligned door lines, and proportional spacing for a uniform look.

A6

Adaptable Production System

Supports RTA, semi-custom, and project orders with reliable lead times.

A7

Attentive Service Support

Pre-sale drawings, technical guidance, and after-sales support reduce client risk.