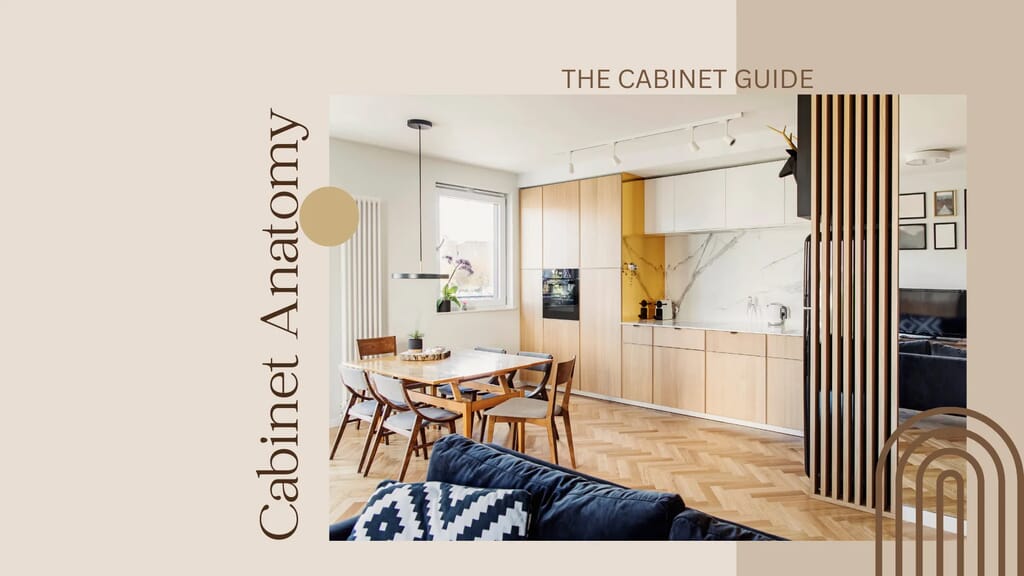

When selecting kitchen cabinetry for the North American market, three construction styles dominate the conversation: Framed cabinets, Frameless cabinets, and Inset cabinets.

Each represents a distinct design philosophy, construction method, and lifestyle preference—none is inherently better than the others. The right choice depends on architecture, space planning, budget, and personal taste.

Below is a clear breakdown of how these cabinet types differ and where each excels.

Framed Cabinets: The Backbone of the American RTA Market

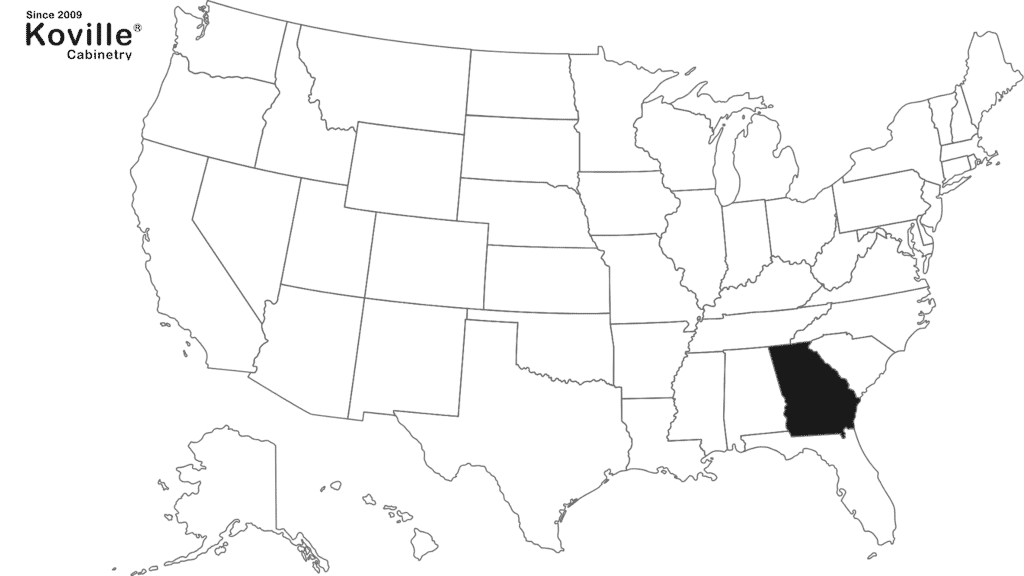

Framed cabinets are the most widely used cabinet construction in the United States, particularly within the RTA (Ready-to-Assemble) category. They are considered the industry standard for both residential and multi-family projects.

A framed cabinet features a solid wood face frame, typically 1-1/2 inches wide, attached to the front of the cabinet box. Doors and drawers are mounted to this frame, creating a familiar and durable structure.

Why framed cabinets dominate the RTA market:

- Cost-effective and reliable

- Structurally stable

- Easy to install

- Widely understood by installers and contractors

This construction reflects traditional American woodworking values—visible wood framing, proven durability, and long-term performance. For builders, dealers, and installers, framed cabinets offer predictability and efficiency, making them the go-to solution for mainstream U.S. cabinetry projects.

Frameless Cabinets: Maximum Space Efficiency for Urban Living

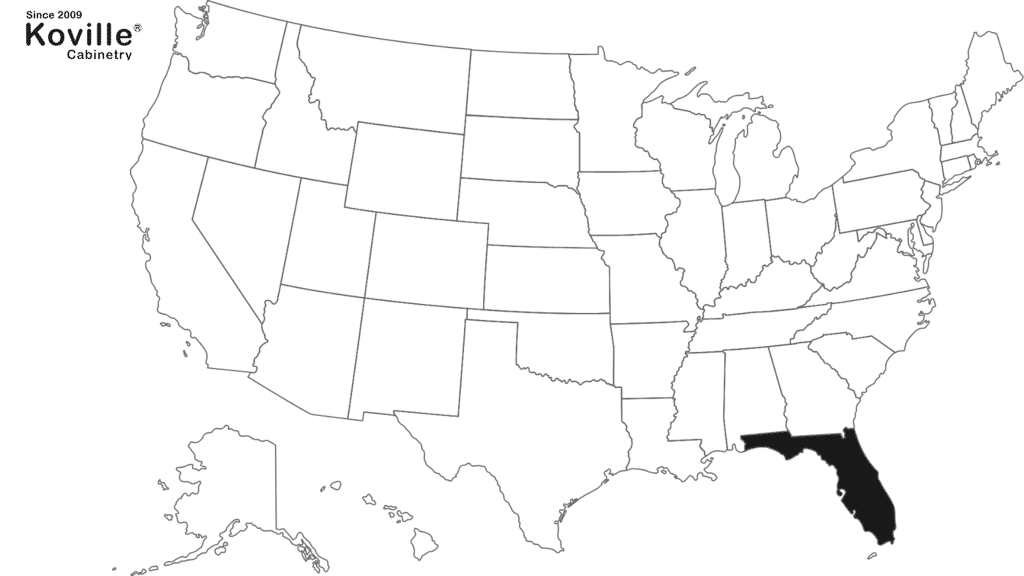

Frameless cabinets—often referred to as European-style cabinets—have gained strong traction in major U.S. metropolitan areas such as New York, Chicago, Boston, Los Angeles, and San Francisco.

These cities share a common challenge: compact living spaces where every inch matters.

Unlike framed cabinets, frameless cabinets eliminate the face frame entirely. Doors and drawers mount directly to the cabinet box, allowing for:

- Wider drawer openings

- Greater interior storage capacity

- A clean, modern appearance

This construction style is especially well-suited for contemporary interiors and space-conscious designs.

Common finishes used in frameless cabinetry include:

- PET panels

- High-gloss PU paint

- Wood veneer

- Melamine paper (for budget-focused projects)

Frameless cabinets prioritize efficiency, precision, and modern aesthetics—making them ideal for urban residences and minimalist architectural styles.

Inset Cabinets: Furniture-Grade Craftsmanship with Timeless Appeal

Inset cabinets trace their origins back to early 20th-century England and represent the most refined form of framed cabinet construction.

Like framed cabinets, inset cabinetry uses a solid wood face frame. However, the defining difference lies in the doors:

Inset doors sit flush inside the face frame, rather than overlaying it.

This requires exceptional precision, tighter tolerances, and higher craftsmanship standards—earning inset cabinetry the reputation of being “furniture-grade”.

Today, inset cabinet design is widely seen in premium furniture and interior brands such as RH and Crate & Barrel, and it continues to dominate the mid-to-high-end custom cabinetry market in the United States.

Inset cabinetry also appears extensively in leading interior design publications, including:

- Architectural Digest

- ELLE Decor

- House Beautiful

Its appeal lies in its timeless proportions, refined detailing, and classic architectural language—making it a favorite among designers and homeowners seeking understated luxury.

Choosing the Right Cabinet Style

There is no absolute hierarchy among framed, frameless, and inset cabinets.

Each serves a different purpose and resonates with different lifestyles, architectural contexts, and design preferences.

- Framed cabinets emphasize durability, value, and familiarity

- Frameless cabinets maximize space and support modern living

- Inset cabinets celebrate craftsmanship and timeless design

At ZASI Cabinetry, we are one of the few Vietnam-based manufacturers capable of producing all three cabinet construction styles within a fully integrated production system.

To learn more about our product lines and capabilities, please visit our Product section for detailed information.